Bondal® Steel is our solution to combine structure born noise-damping with cladding material.

Usage of Bondal® Steel meets the need to create a higher comfort level in an easily applicable and an environmental friendly method.

Bondal® Features

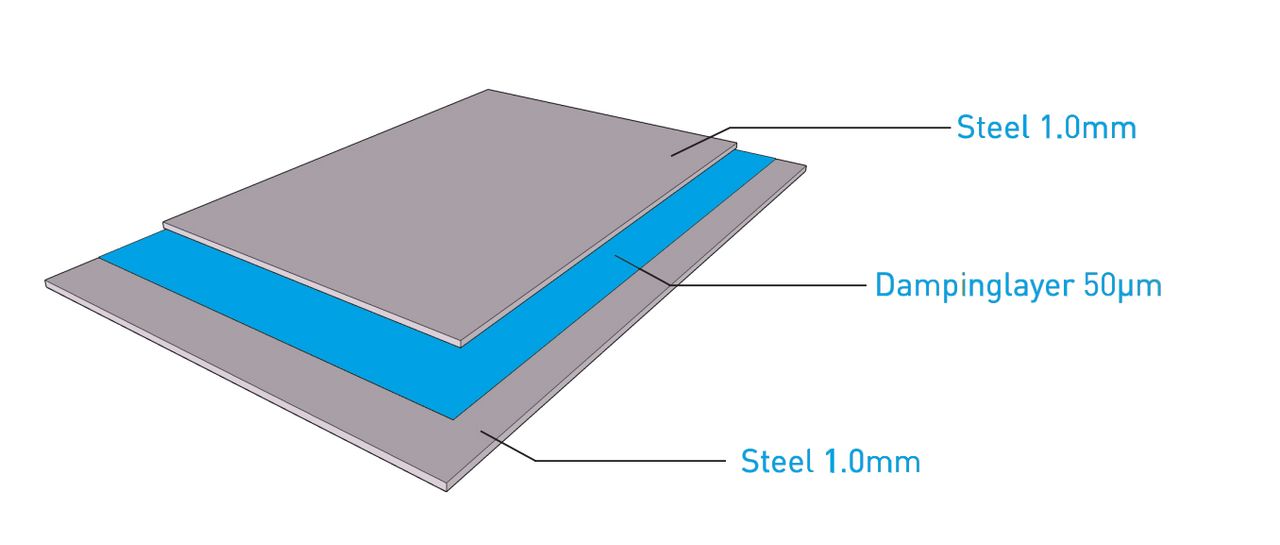

How is it made?

Multi-layer damping material is proven to be the best way to realise a high damping. Therefore our product developments are based on this method. To minimize the onboard labour, we deliver our products in the multilayer version.

Bondal® Applications

Industrial

Industrial

Vibration damping of low-frequency energy in any used substrate surface of industrial machinery or casings.

Nautic

Nautic

Structure born noise damping of decks, bulkheads and other surfaces for steel, aluminium or composite yachts.

Automotive

Automotive

Damping of body parts such as doors, roof, firewall and trunk. Also vibration reduction in suspension systems.