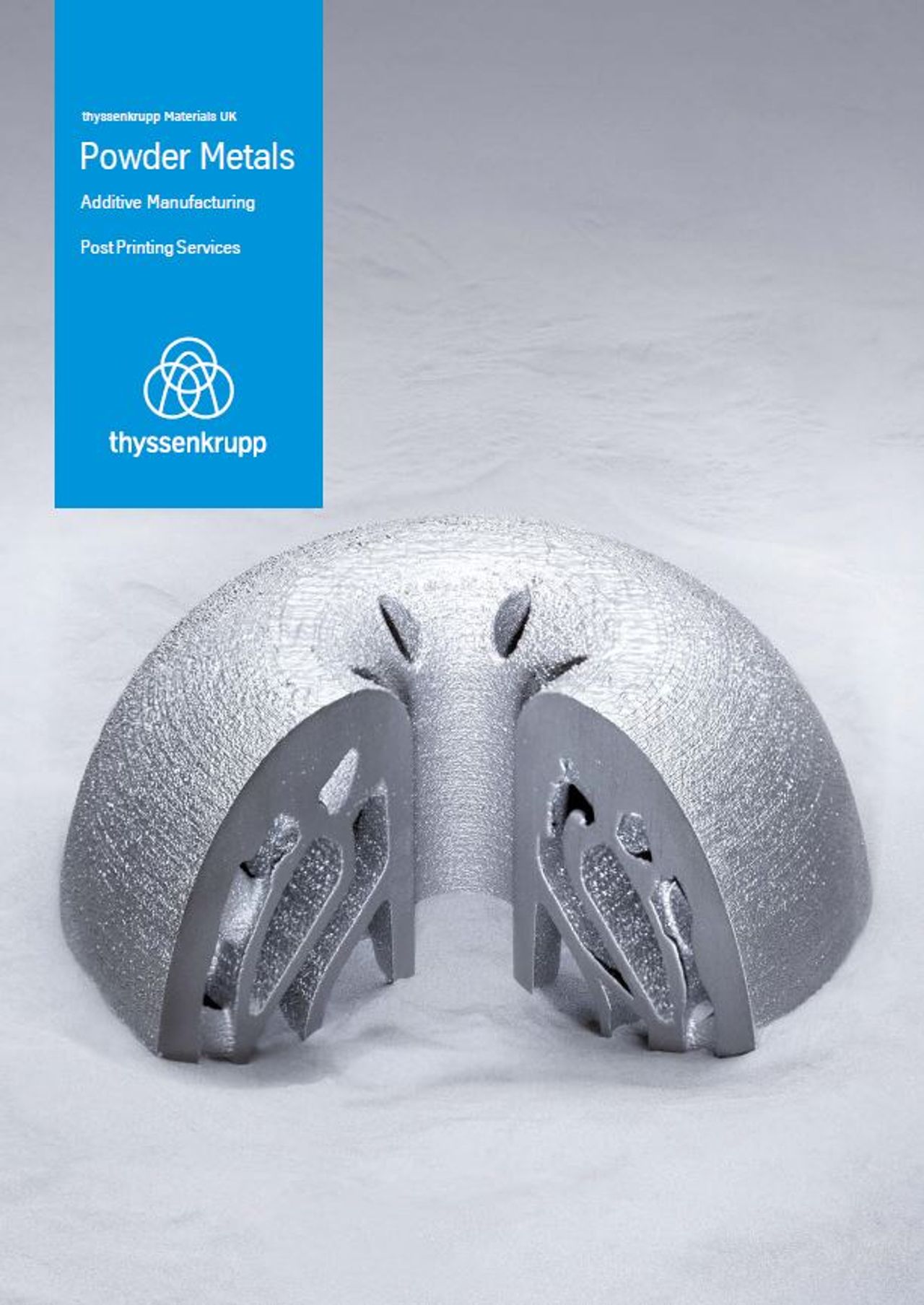

Additive Manufacturing

thyssenkrupp Materials UK – Your one stop shop for metal additive manufacturing

From material selection and supply to finished parts

With the rapid growth of metal additive manufacturing, our advanced metal powders are matched to the different machine types and the underlying processes, enabling us to supply you with the ideal powders for your printing process. But there are many more advantages to purchasing powders and additive services from us:

short delivery times

consistently high and monitored quality

optimised logistics worldwide

sustainable sourcing

We can support your whole metal additive manufacturing supply chain.

Our clients are using metal additive manufacturing technology to develop prototypes, short run manufacturing and complex one off designs for science, engineering, aerospace, repair and maintenance.

Metal Powders Portfolio

| Standard materials | |||||

|---|---|---|---|---|---|

| Name | DIN/EN | Type | Category | Strength range Rm (Mpa) Rp0,2 (Mpa) | Approximate Vickers hardness (HV 10) |

| 316L | 1.4404 | Austenitic | stainless | 590 – 660 490 – 540 | 205 |

| 17-4PH | 1.4542 | Ferritic Cr steel | stainless, hardenable | 750 – 910 550 – 590 | 220 |

| 1.2709 | 1.2709 | Maraging steel | martensitically hardenable tool steel | 970 – 1,050 750 – 900 | 320 |

| Inconel 625 | 2.4856 | Ni-base alloy | high corrosion resistance | 920 – 1,000 660 – 750 | 285 |

| Inconel 718 | 2.4668 | Ni-base alloy | high corrosion resistance, high-temperature material | 950 – 1,030 640 – 770 | 295 |

| AlSi10Mg | 3.2382 | Aluminium alloy | lightweight structural material | 220 – 420 180 – 220 | 115 |

| Ti6Al4V | 3.7164 | Titanium alloy | high-strength lightweighting | 830 – 1,100 910 – 1,200 | up to 385 |

We hold our standard range of metal powders in-stock for immediate availability.

Further powder materials include:

Ferro alloys

Carbides

Nitrides

Refractory metals

Soft magnetic alloys

Ni-base alloys

Ti alloys

Al alloys

Amorphous alloys

In addition to the standard materials commonly used for 3D printing today, thyssenkrupp Materials UK has a wide range of modification capabilities with regard to alloy structure, atomization and subsequent powder processing that allow us to manufacture and supply custom powders in batches from 50 kg. Ideally, modifications of this kind are carried out, tested and approved in close collaboration with the customer. Contact our experts today for advice on custom metal additive manufacturing powders.

Note: Strength and hardness properties strongly depend on heat treated condition of the manufactured part.

The best material quality ensured

thyssenkrupp’s central laboratories are certified to DIN EN ISO/IEC L7025:2005. All the powders we supply are subject to strict quality controls. The aim is to reduce the batch dependency of the powder properties to a minimum. Certificates of compliance can be included with deliveries.

Download our brochure:

Post Printing Services

Producing metal 3D printed parts often requires additional industrial processes, which thyssenkrupp Materials UK has years of experience with. Methods like metal cutting and heat treatment are used to relieve internal stresses, have the metal support structures removed and finish the printed components.

We offer a full post build machining and turning service on all additive manufactured metal parts to ensure product performance as per the design. thyssenkrupp Materials UK uses state-of-the-art technology to bring custom CNC machining to the metal additive manufacturing market. Our network of sites across the UK allows us to offer capacity and competitive prices. It also means that we can produce both complex prototypes and low-volume production runs of 3D printed metal parts, with many surface finishes.